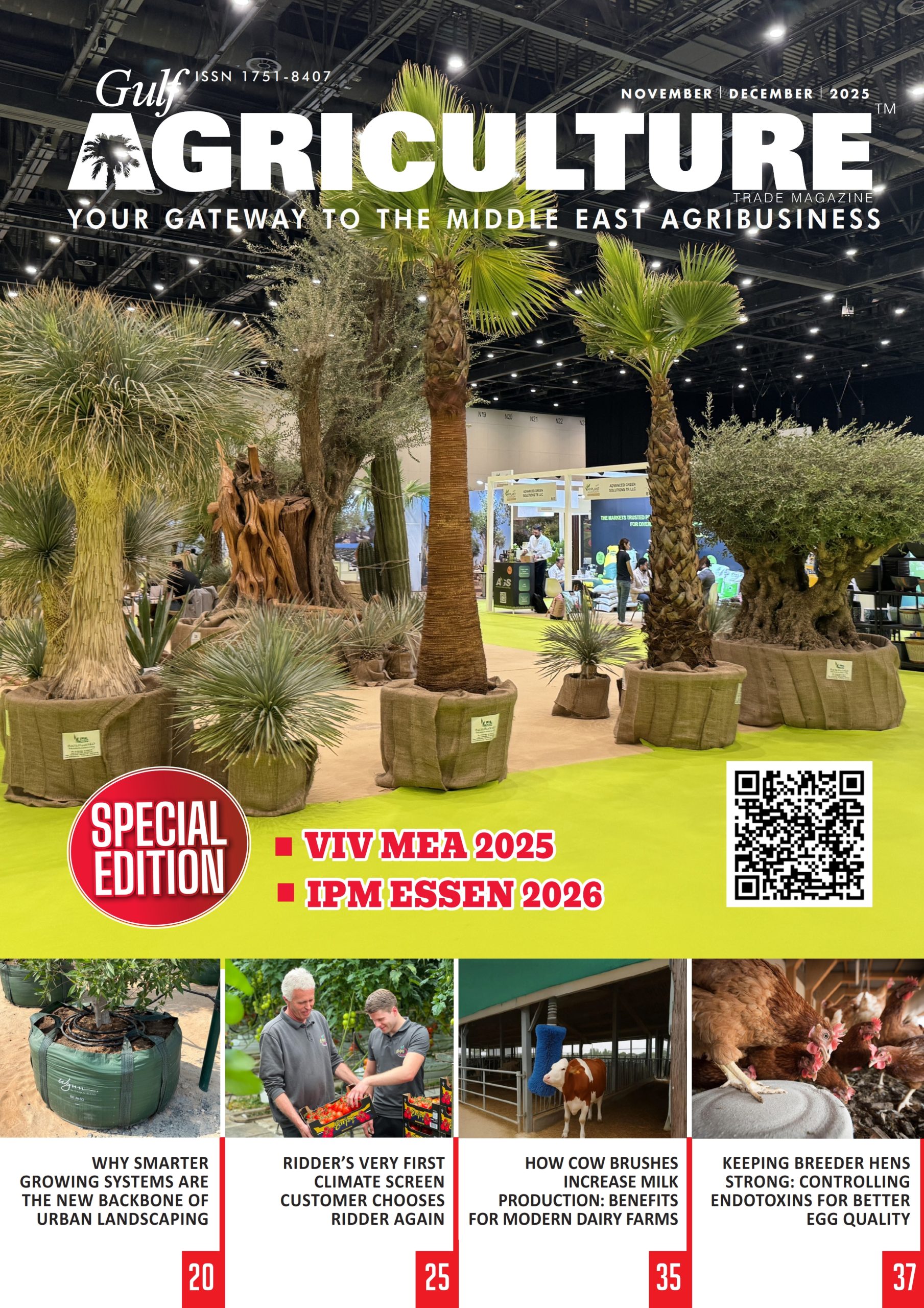

In 2015, a new manufacturer of climate screens entered the market: Ridder. It wasn’t an illogical move. Until then, hundreds of screen installations had already been operating with Ridder-brand motors. But it was a bold move too, entering a market dominated by just two major players. Ten years later, Ridder has become one of those “big” names, offering a complete range of screens. All produced in Maasdijk, working closely with suppliers and partners abroad. But who was the very first customer?

“That was us,” says Geert van Rens, who in 2015 installed 6 hectares of RES10 FR screen fabric. At their tomato nursery in Meterik, Van Rens cultivates medium truss tomatoes of the Bronski variety. Under the brand name “Enjoy,” these tomatoes are distributed to buyers through Staay Food Group, a fruit and vegetable wholesaler. The family business already had experience with screens, but not with Ridder. “No, but of course we already knew Ridder from the motors for screening and ventilation. The contact came through Maurice Kassenbouw, a trusted partner for us. Maurice had confidence in Ridder, and at that time there was also some price pressure in the screen market.”

“It has to end at some point”

Coincidentally, this autumn Van Rens plans to replace the screen. Ten years is now a respectable age for a screen fabric. Many growers choose to replace their fabric every five years. “Indeed, after ten years you notice the light transmission decreases a bit. But in terms of quality and moisture permeability, it’s still an excellent screen for us,” says Jordi van Rens, who took over management from his father after two and a half years. Geert agrees that the Ridder screen could use an upgrade. “Slowly but surely, small holes start to appear in the fabric. It’s getting dirtier, and here and there a bit stiffer. It has to end at some point.”

A changed cultivation strategy

The fabric may be the same, but the cultivation strategy at Dwarsweg in Meterik has changed. “Quite drastically,” says Geert. “Mainly due to energy use. In spring, we always use an OPAC film in addition. That’s because we start late, we only plant in the second or third week of January. When you start late, you need a higher average day temperature in the greenhouse. You can’t achieve that with just a screen. In autumn, we use the screen the most.”

The same screen stays

Jordi is now responsible for screening, and for choosing a new fabric, possibly even a new supplier. “But our trust in Ridder has never been disappointed,” he says about the decision to go with the Westland-based manufacturer again. Ridder is no longer the newcomer it once was. In ten years, the company has significantly expanded its product range and customer base. Today, Ridder screens cover roughly 10,000 hectares of greenhouses worldwide, all manufactured in Maasdijk since 2015.

Up to 47 percent energy savings

After ten years, the RES10 FR remains a cornerstone in Ridder’s range. There has never been a reason to change the “Ridder Original,” the company explains. The Ridder Energy Saving Screen can significantly reduce energy consumption, while maintaining a consistent growing climate and optimal temperature distribution. Light interception is minimal, as the fabric folds neatly. Other advantages include its flame-retardant properties and UV resistance. Jordi concludes: “We’re very satisfied with this screen. There’s really no reason for us to switch. There’s also the RES10+ FR, the newer type, which lets through slightly less moisture because it uses 5 mm film instead of 4 mm. That means less yarn, resulting in lower moisture permeability and extra energy savings. For tomato cultivation, though, the RES10 FR remains the better option. But of course, growing will be a bit different again with a completely new screen.”

For more information about Ridder climate screens, visit https://ridder.com/en/climatescreens.

About Ridder

Ridder has been a pioneer of innovation in greenhouse and farming technologies since 1953. Today, we offer a wide range of essential systems and solutions. Our mission is, working together for sustainable growth.